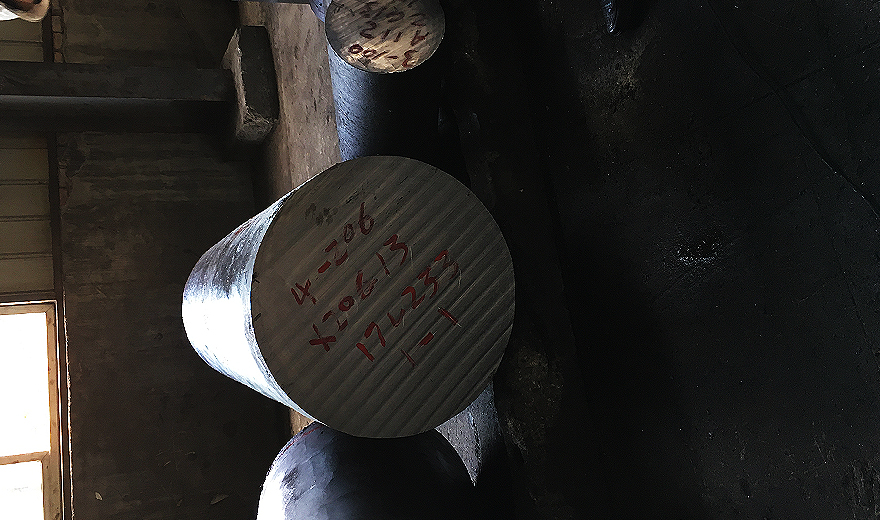

55NiCrMoV7, 1.2714 Hot-working tool steel with high impact strength, ductility, very good hardenability, High resistance to high temperatures as well as temperature differences occurring during operation.In in the metallurgical industry, where high mechanical properties are also required, and low tendency to deformation during heat treatment.The grades are used in the production of forging machine components - forging dies, parts of extrusion presses, hot knives or deburring plates.

WNLV, WNL, WNL1, 56NICRMOV7, 55NICRMOV7, 56 NICRMOV 7, 55 NICRMOV 7, 1.2714, 1.2713, 55NCDV7, 55NICRMOV6, 55 NICRMOV 6, NK, SKT4, MOCN15, CSN 19662, 5CRNIMO, BH 224/5, 55VMOCRNI16, 55MOCRNI16, T61206, 5CHNM, 5KHNM, 5ХНМ