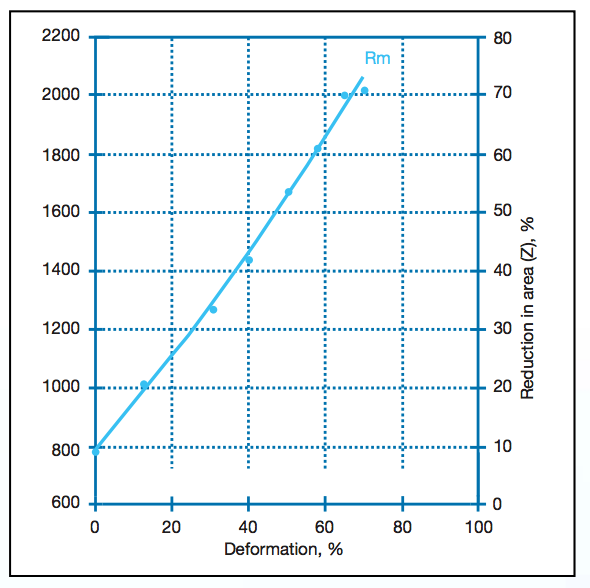

1.4310 is essentially a leaner version of 1.4301, which as a result of its combination of high chromium and restricted nickel content, produces a metastable austenitic structure which will work harden / strengthen very rapidly when subjected to cold deformation. Since this steel is used for the production of spring components, the final microstructure will contain a significant amount of shear induced martensite and as such will be relatively magnetic.

Heat treatment and mechanical properties

Optimal material properties are realised after solution annealing in the temperature range 1000 °C – 1100 °C followed by rapid cooling in air or water. Since this grade of steel is susceptible to precipitation of chromium carbides, care must be taken to limit the time spent in the temperature range 450 °C to 850 °C, both during fabrication and service. In the solution annealed condition, the following mechanical properties may be attained when testing in the longitudinal direction:

Applications

Automotive industry,Various corrosion resisting spring components,chemical industry,food and beverage industry,electronic equipment

Elevated temperature properties

Welding

Since 1.4310 is primarily used for the production of springs, there is generally no requirement for welding. Should welding be required, however, 1.4310 is weldable with or without the use of filler material. If the use of a filler metal is required, then the use of Novonit 4316 (AISI 308L) would be recommended. A maximum interpass temperature of 200 °C must be adhered to. Post weld heat treatment is not necessary. Please note that welding of cold worked components will result in the welded zone displaying significantly reduced mechanical properties compared with the rest of the weldment.

Forging

1.4310 is usually heated to within the range 1150 °C – 1180 °C to allow forging to take place at temperatures between 1200 °C and 900 °C. Forging is followed by air cooling, or water quenching when no danger of distortion exists.

Machining

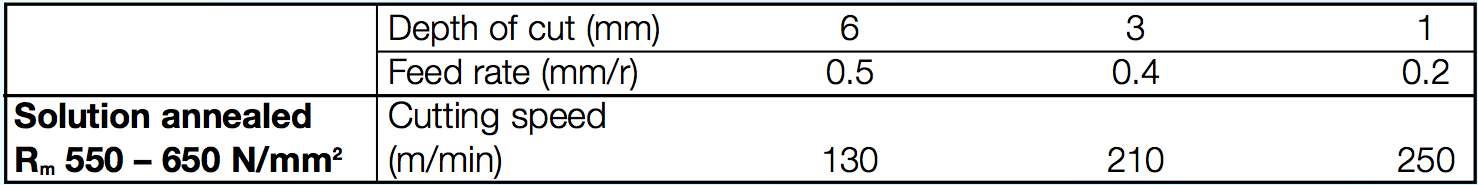

The combination of low thermal conductivity and extremely high work hardening rate serves to make 1.4310 difficult to machine. The following cutting parameters are thus proposed as a guideline when machining NIRO-CUT® 4310 using adequate cooling and coated hard metal cutting tools.